If you need any help, please feel free to contact us

Introduction WPC (Wood Plastic Composite) composite decking boards have become a popular choice for outdoor decking, known for their durability, low m...

READ MORE

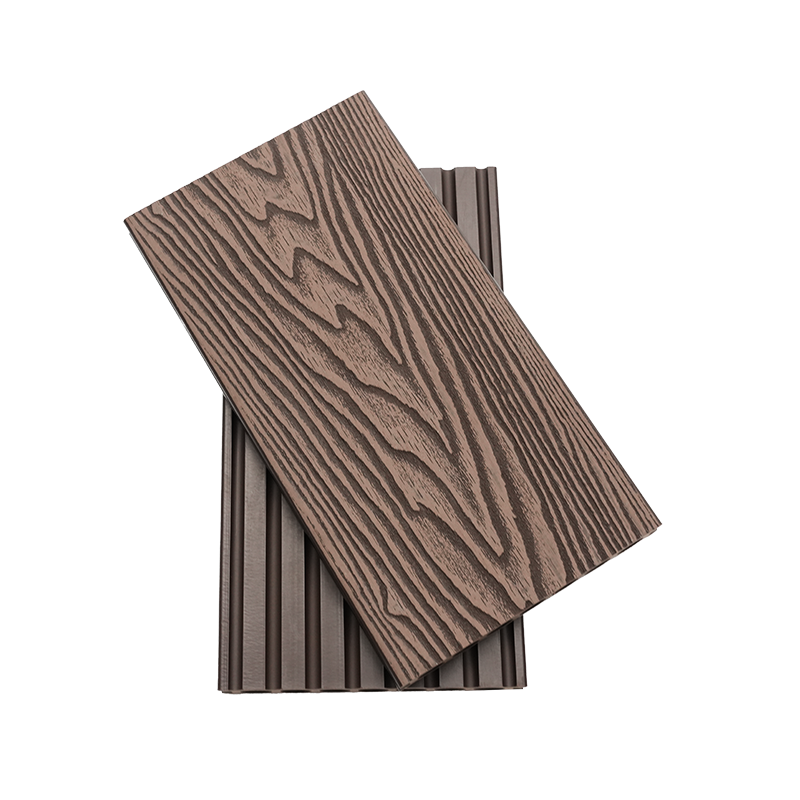

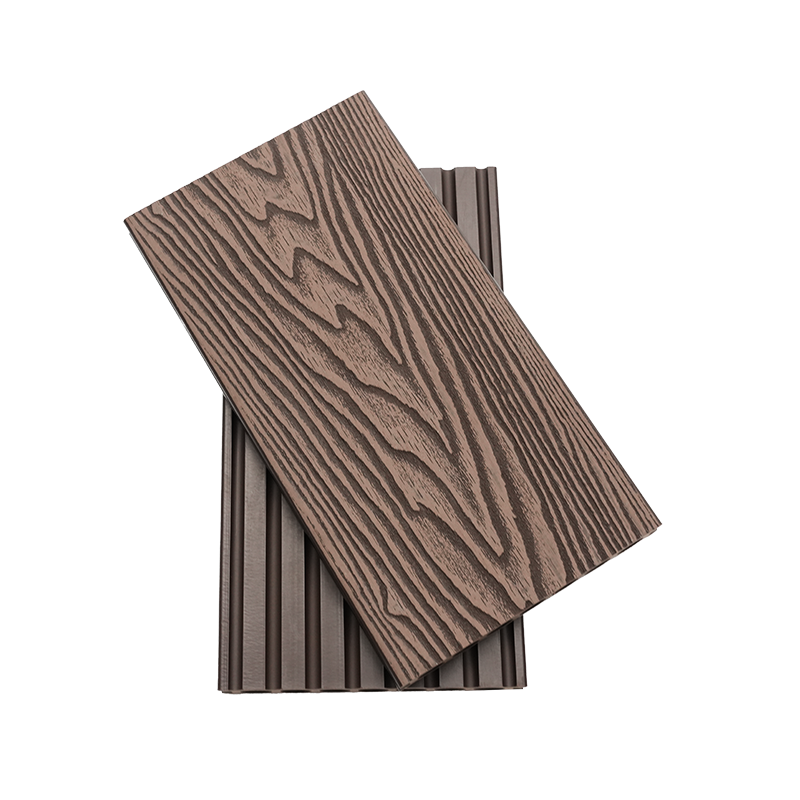

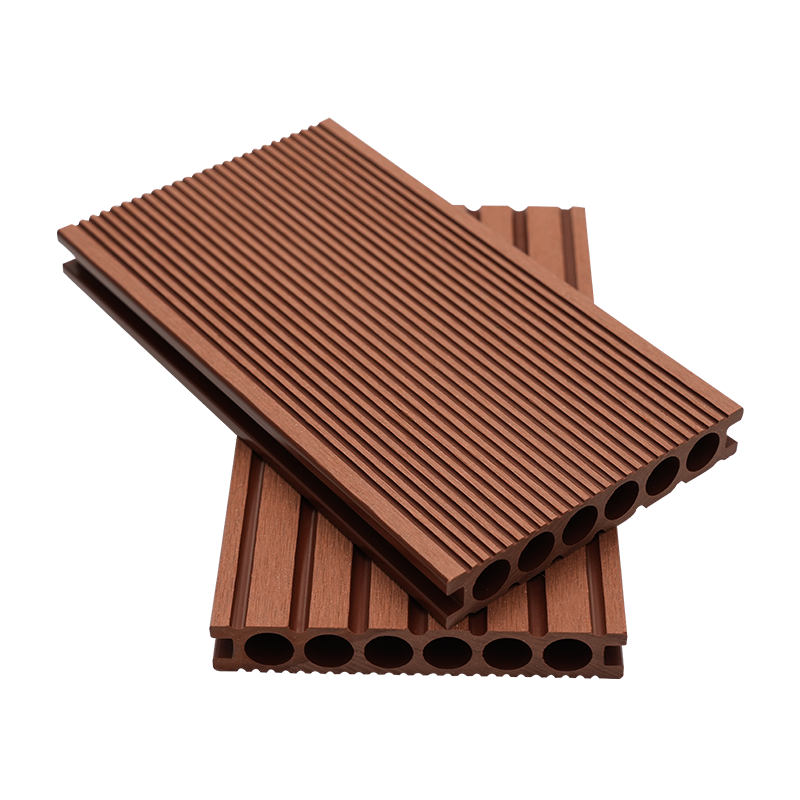

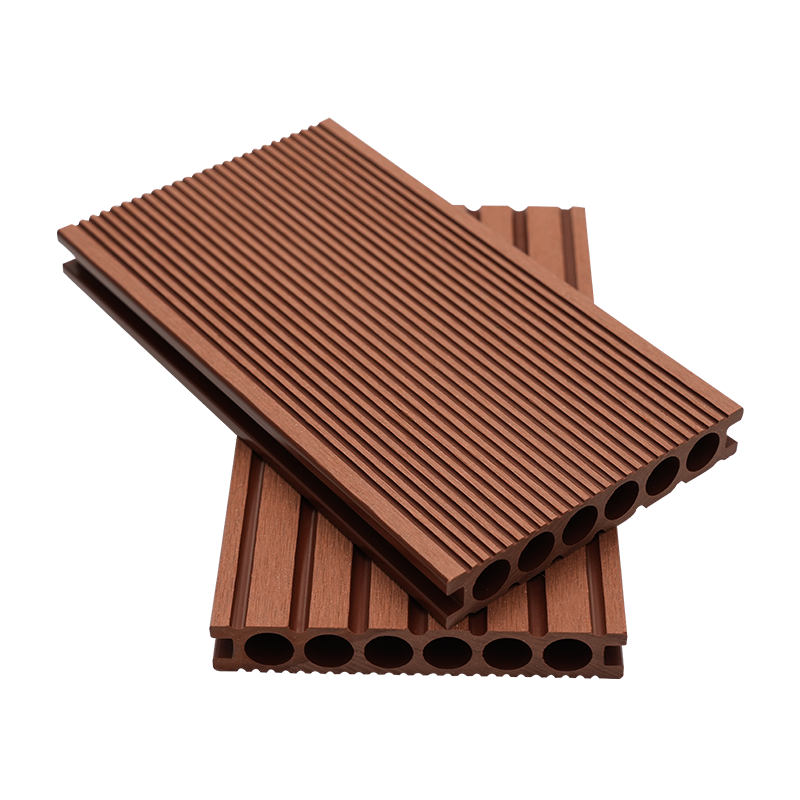

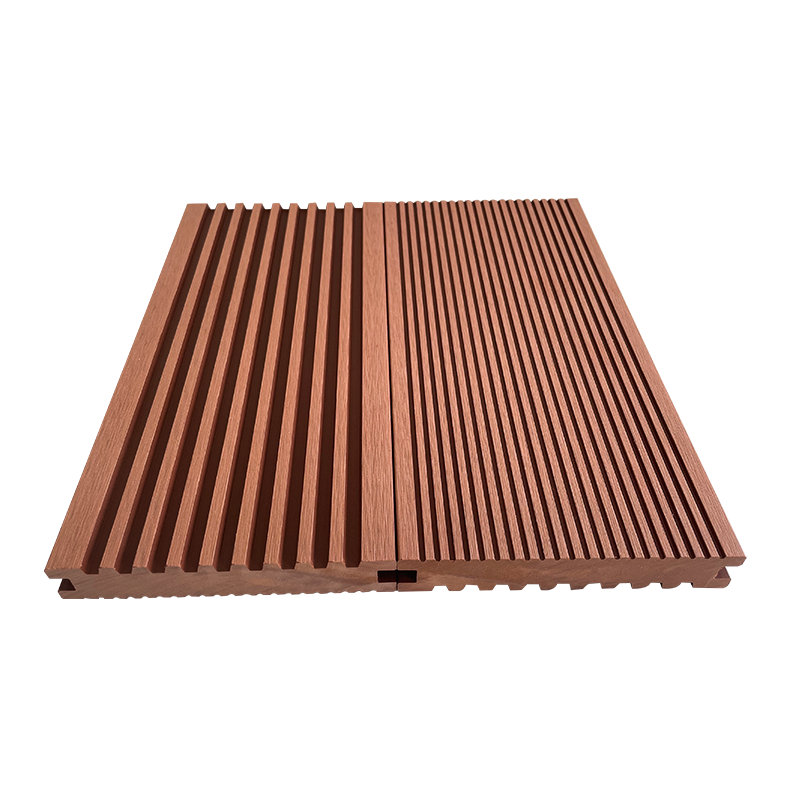

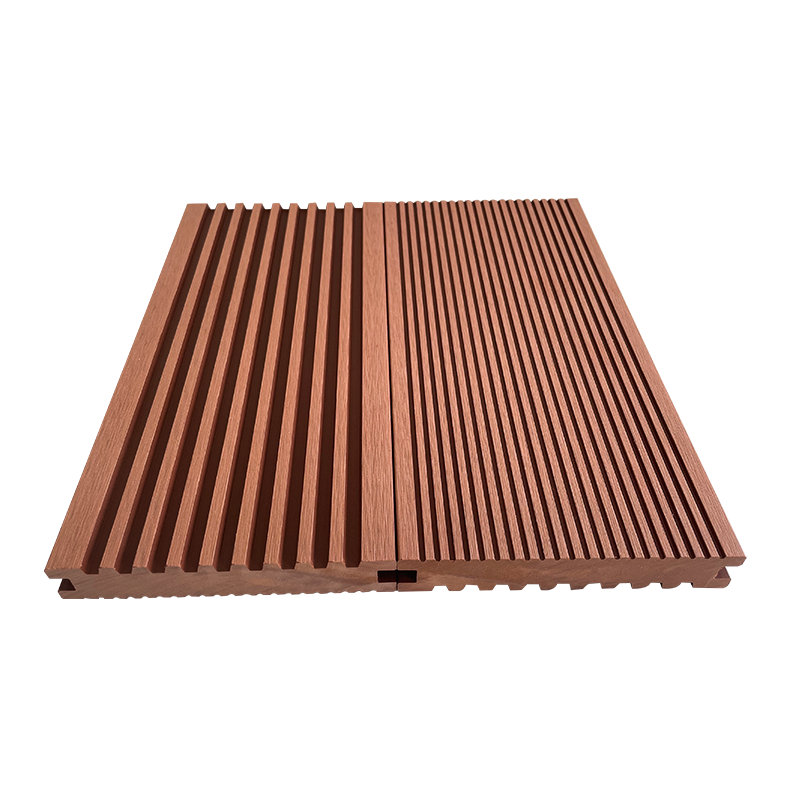

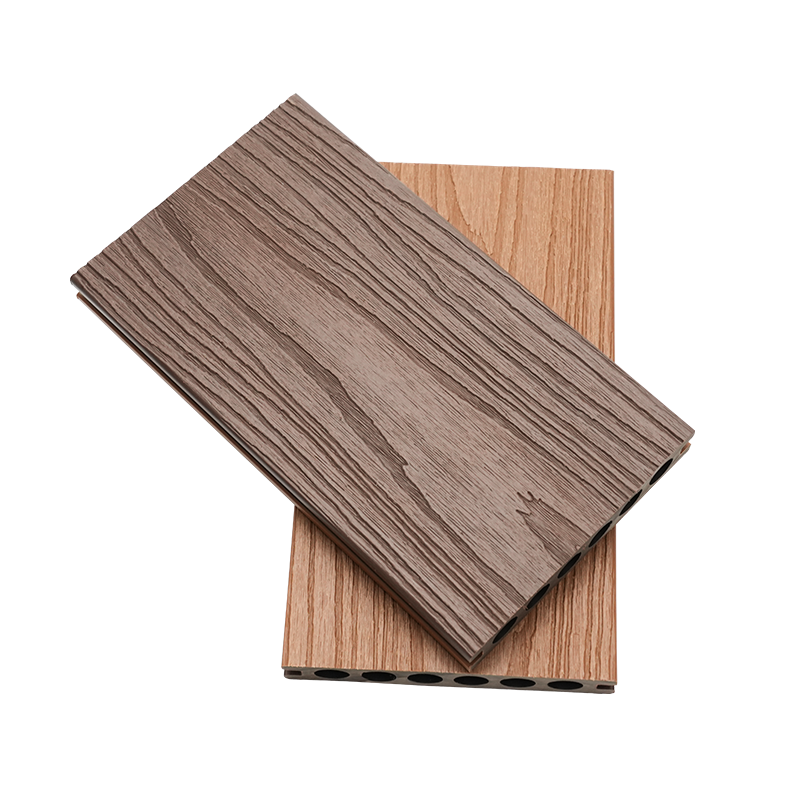

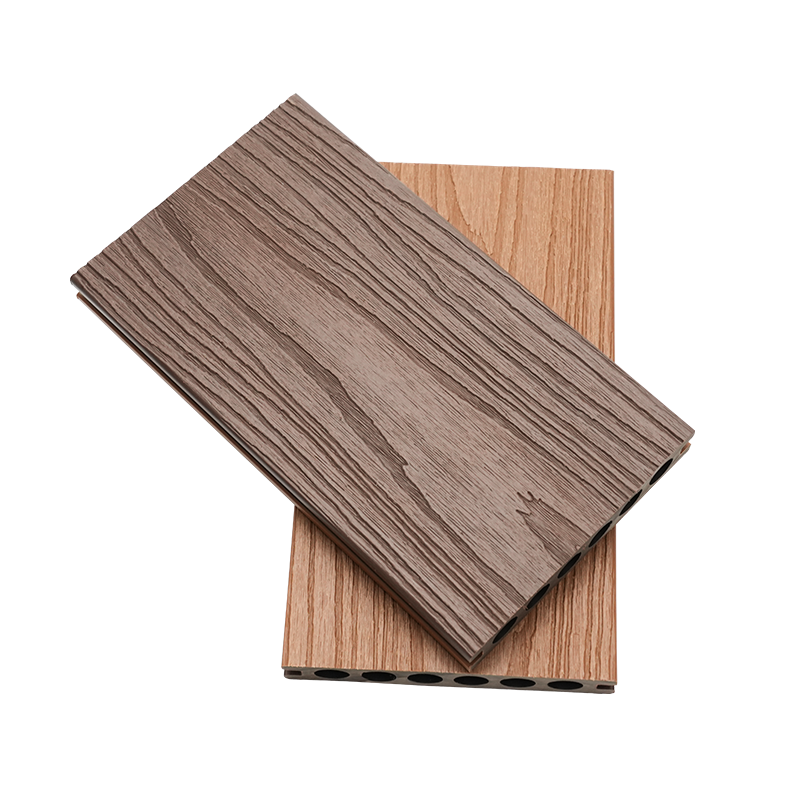

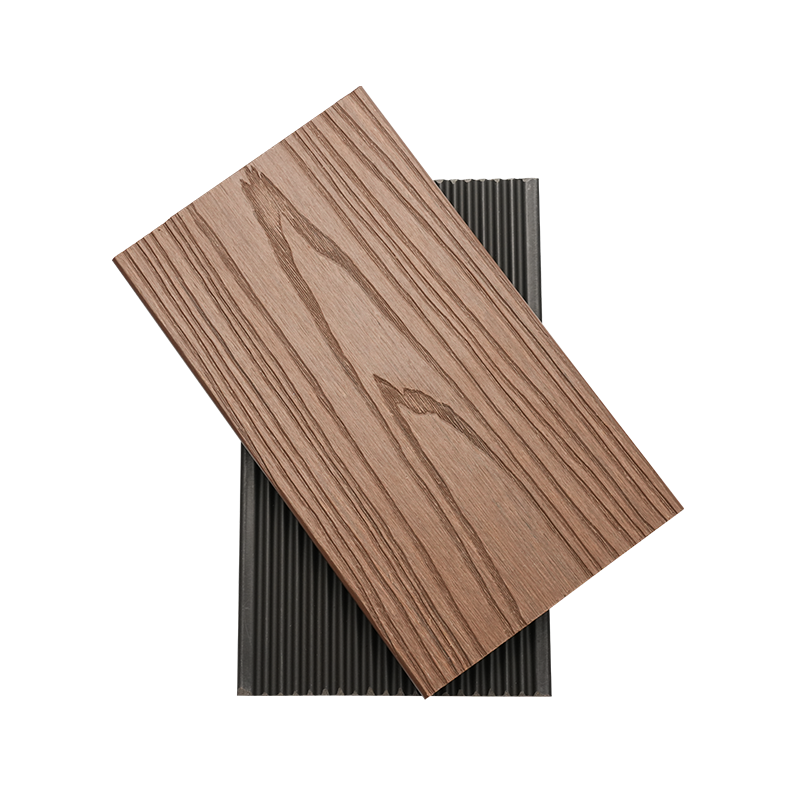

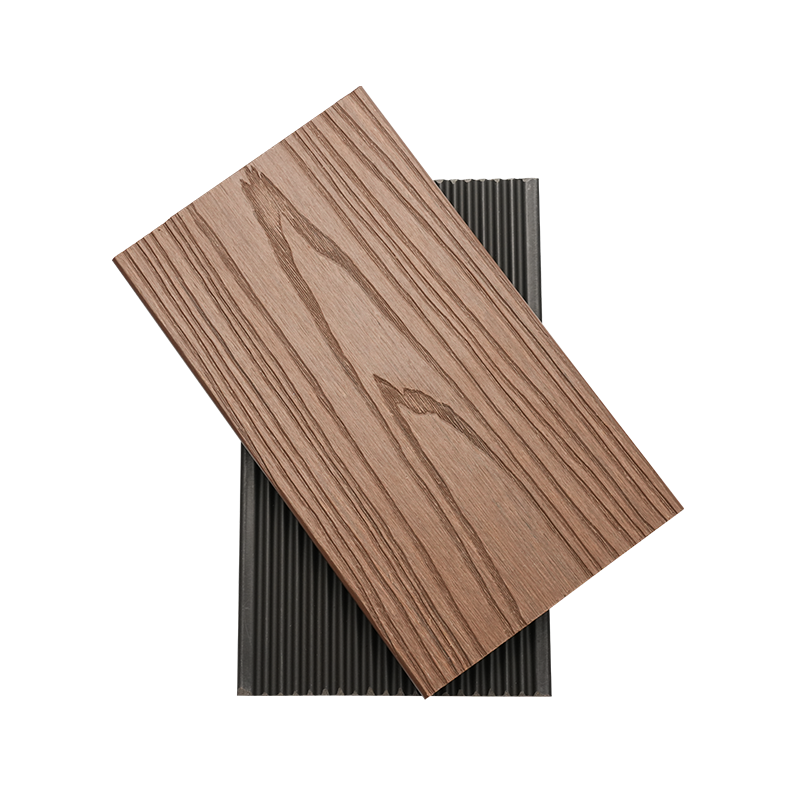

Wood plastic decking is a high-performance floor decoration material. It uses a composite material of wood fiber or wood powder and polymer plastic (mainly polyethylene, polypropylene, etc.). Through precise proportioning and high-temperature extrusion molding technology, it can achieve a realistic simulation of the texture and feel of natural wood, and improve the physical stability and durability of the material. Wood plastic flooring overcomes the defects of solid wood flooring such as easy moisture, deformation, and cracking. Its surface treatment technology ensures that the material has excellent wear resistance and scratch resistance, effectively extending its service life. In terms of color and texture, wood plastic flooring can provide users with a wealth of choices to meet the design requirements of different styles and needs. Wood plastic flooring performs well in outdoor applications, is not easy to fade or age, and provides a lasting decorative effect for outdoor spaces.

Introduction WPC (Wood Plastic Composite) composite decking boards have become a popular choice for outdoor decking, known for their durability, low m...

READ MOREIntroduction In the world of interior design, selecting the right materials for wall coverings is crucial. The traditional options, such as paint, wal...

READ MOREIntroduction When it comes to designing an outdoor space, one of the most important decisions is selecting the right decking material. WPC composite d...

READ MOREAs homeowners look to enhance the outdoor spaces of their properties, one material that has gained considerable attention is outdoor solid wood plasti...

READ MOREIntroduction In recent years, the construction industry has been undergoing a significant transformation as sustainability and efficiency become param...

READ MOREThe quest for the perfect decking material is a significant consideration for homeowners, architects, and builders alike. For decades, the battle has been between traditional wood and its modern alternatives. In recent years, one material has surged in popularity, promising the best of both worlds: WPC Composite Decking. But what exactly is it, and does it live up to the hype? This article delves deep into the science, benefits, and considerations of WPC Decking to provide a comprehensive answer.

This fusion is the key to its performance. The plastic component provides resistance to moisture, rot, and insects, while the wood fiber offers the natural texture, rigidity, and feel of real wood. The additives ensure the components bind effectively and enhance the material’s durability and UV stability.

1. Unmatched Durability and Longevity: The plastic matrix makes WPC highly resistant to the elements. It does not absorb water like natural wood, which means it won’t rot, warp, crack, or splinter. It is also impervious to wood-boring insects like termites, eliminating a major concern for homeowners. This inherent resistance translates to a significantly longer lifespan with minimal degradation.

2. Minimal Maintenance Requirements: This is perhaps the most significant selling point. A traditional wood deck requires annual power washing, sanding, and re-staining or sealing to maintain its appearance and structural integrity. WPC Decking, however, requires none of that. Routine cleaning with soap and water is typically sufficient to remove dirt and grime. This saves considerable time, effort, and long-term maintenance costs.

3. Consistent Color and Slip Resistance: The color in WPC is not a surface stain; it is pigmented throughout the entire board (known as solid-through color). This means that minor scratches, scuffs, or wear over time are far less noticeable than on stained wood. Furthermore, most WPC boards are manufactured with a textured or embossed surface that provides excellent slip resistance, even when wet, enhancing safety around pools and patios.

4. Environmental Considerations: WPC makes use of recycled materials. The wood fibers often come from waste products of lumber mills, and the plastic can be sourced from post-consumer or post-industrial recycled content. This reduces waste destined for landfills and lessens the demand for virgin timber and plastic.

1. Initial Cost Investment: The upfront cost of WPC Composite Decking is generally higher than that of pressure-treated pine or even some softwoods. However, this must be evaluated against the drastically reduced maintenance costs over the deck’s lifetime, often making it more economical in the long run.

2. Heat Retention: Like many decking materials, including wood, darker colors of WPC can become hot under direct sunlight. However, many modern manufacturers offer lighter color options and technologies that incorporate cooling agents or more reflective surfaces to mitigate heat absorption.

3. Structural Considerations: While incredibly strong, WPC is not as rigid as solid hardwood. Therefore, proper installation is crucial. Joist spacing must adhere strictly to the manufacturer’s specifications to prevent sagging or bouncing under weight.

The global push for sustainability is also driving innovation in this sector. Companies are investing in research to increase the percentage of recycled content without compromising performance and to explore bio-based polymers. In this dynamic landscape of material science, manufacturers are consistently pushing the boundaries of what WPC can achieve. For instance, industry participants like Jiangsu Xuanhui New Material Technology Co., Ltd. are deeply involved in the research and development of advanced composite formulas, focusing on enhancing weatherability and eco-friendly profiles to meet evolving market demands.