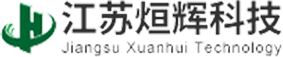

Is Six Hole Straight-Grained Wood Plastic Decking the Smarter Choice for Modern Outdoor Spaces?

Why Decking Choices Matter More Than Ever

Outdoor living spaces have shifted from being luxury add-ons to essential parts of modern homes and commercial projects. Families are investing in patios, pool surrounds, and garden platforms as extensions of indoor living, while businesses—from cafés to resorts—rely on durable decking to enhance customer experiences. In this context, the choice of decking material goes far beyond aesthetics. It determines safety, long-term costs, and even environmental impact. Among the new-generation options, Six Hole Straight-Grained Wood Plastic Decking has emerged as a carefully engineered solution that blends science, sustainability, and style.

Engineering Principles Behind the Six-Hole Design

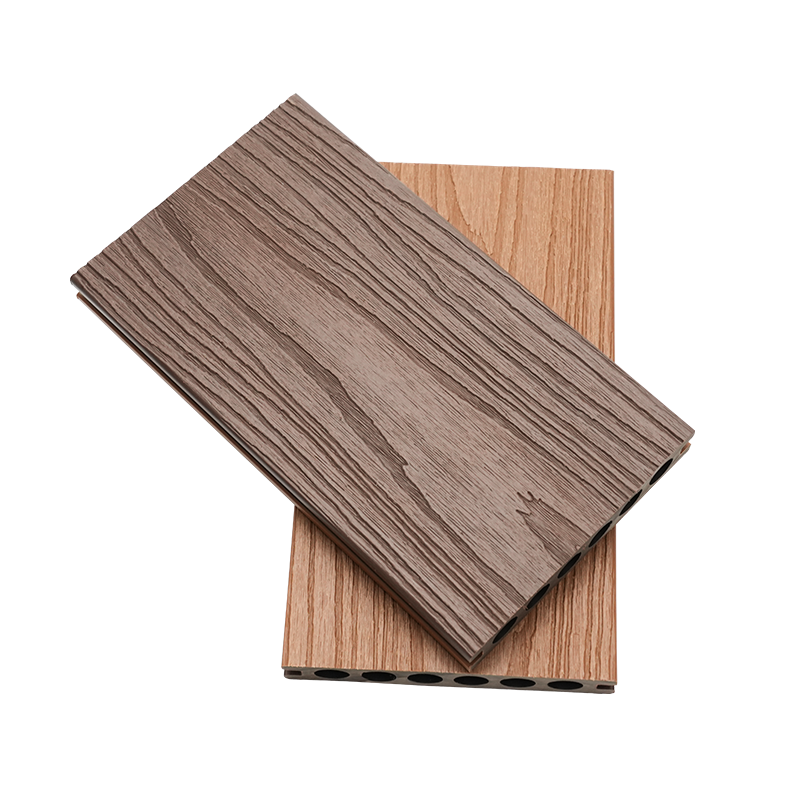

At the heart of this decking is an intelligent structural profile: six evenly spaced hollow channels running lengthwise through the board. This configuration is not decorative—it is calculated engineering.

- Strength-to-Weight Optimization: By placing material only where it contributes to structural strength, the design achieves rigidity comparable to solid boards while reducing weight by up to 30%.

- Thermal Stability: Air circulation within the channels helps moderate heat expansion. Field studies show that six-hole boards expand less than traditional composites, minimizing buckling in hot summers.

- Water Management: The hollow structure creates natural drainage paths, preventing surface pooling and lowering the risk of mold or mildew.

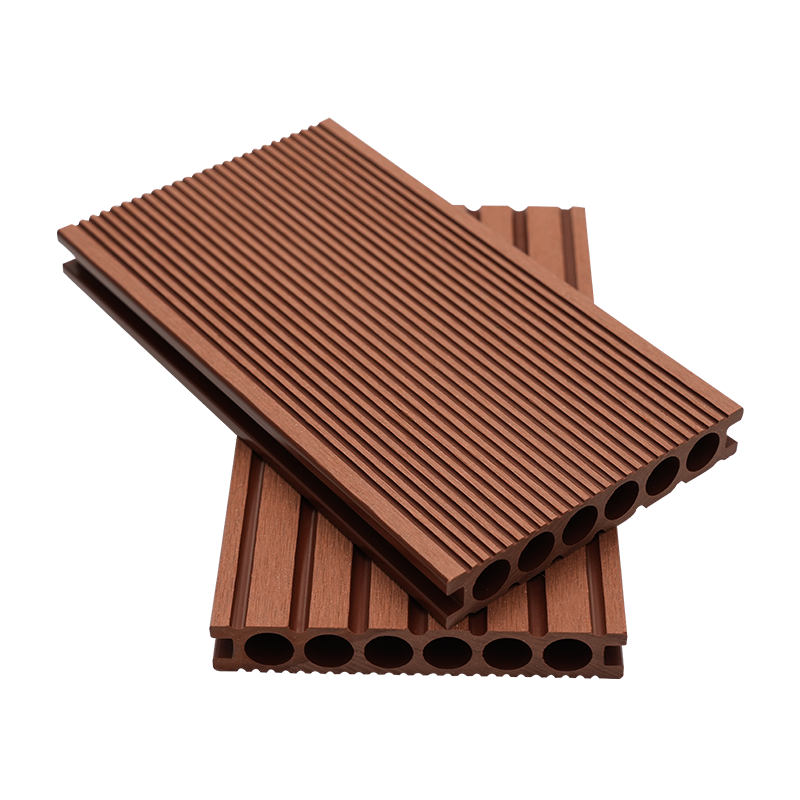

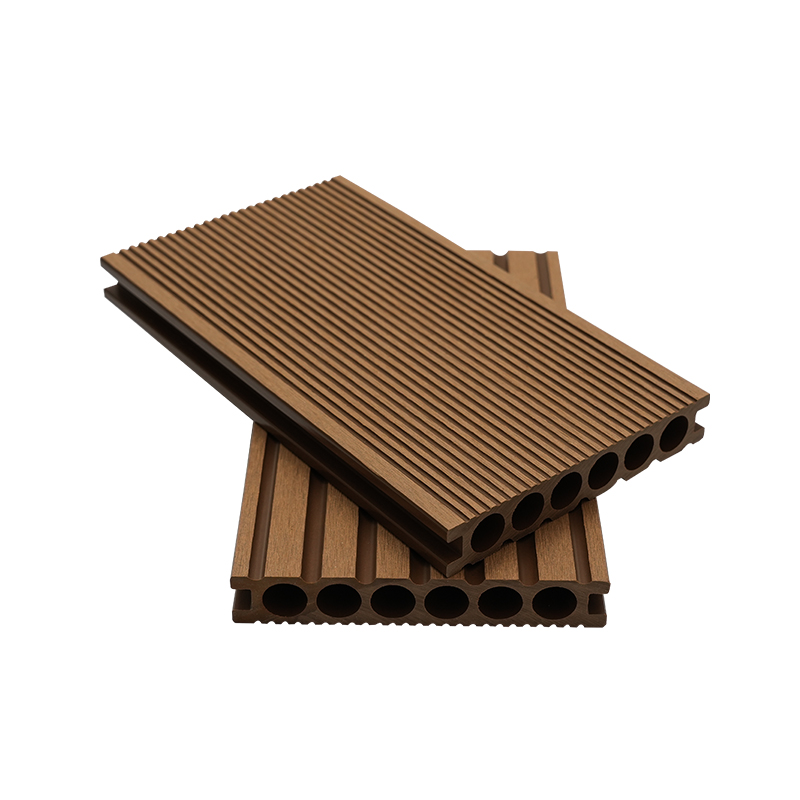

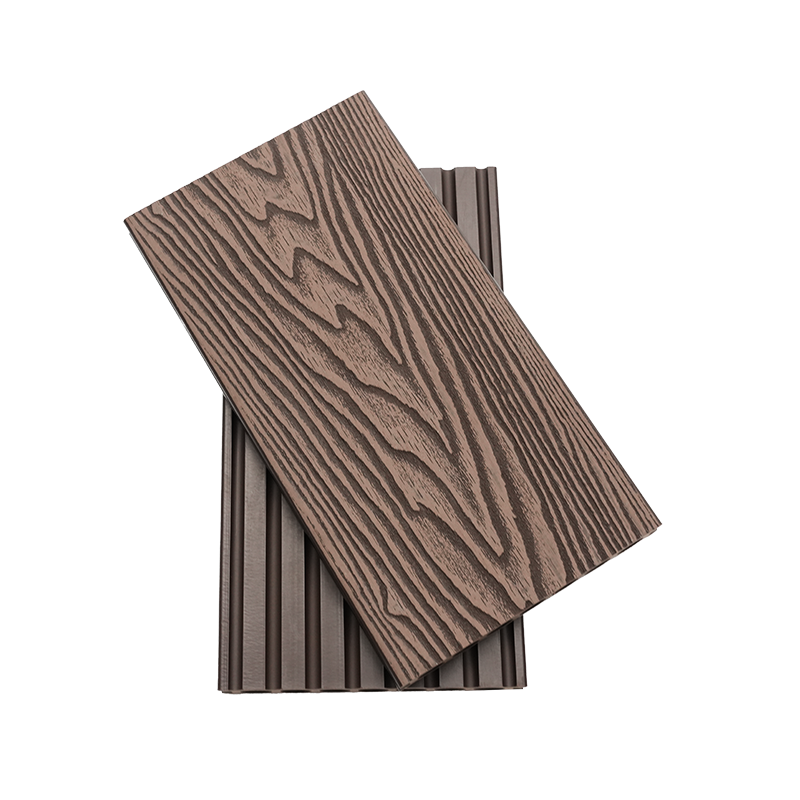

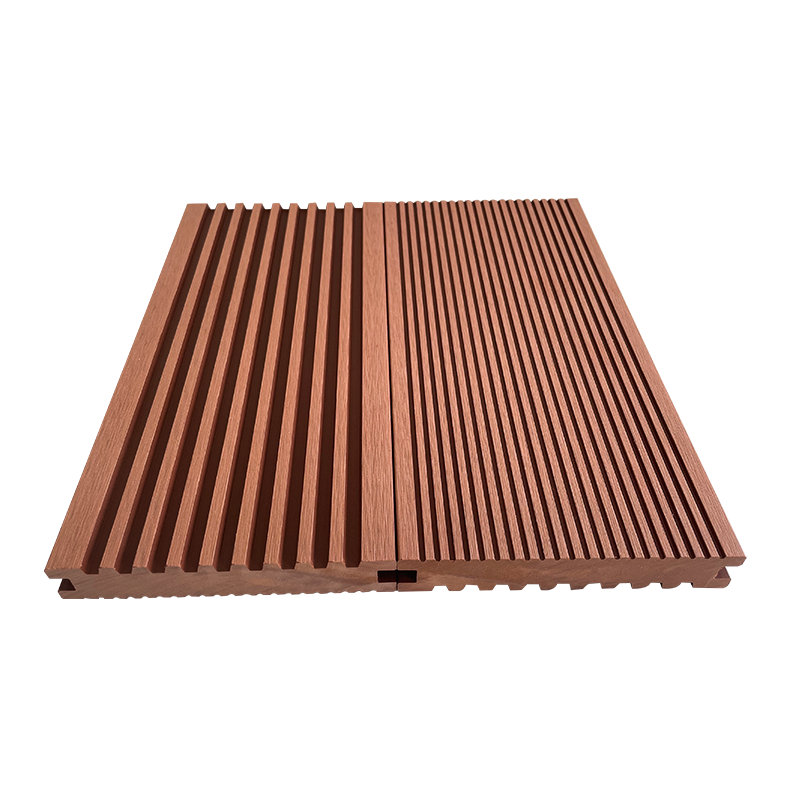

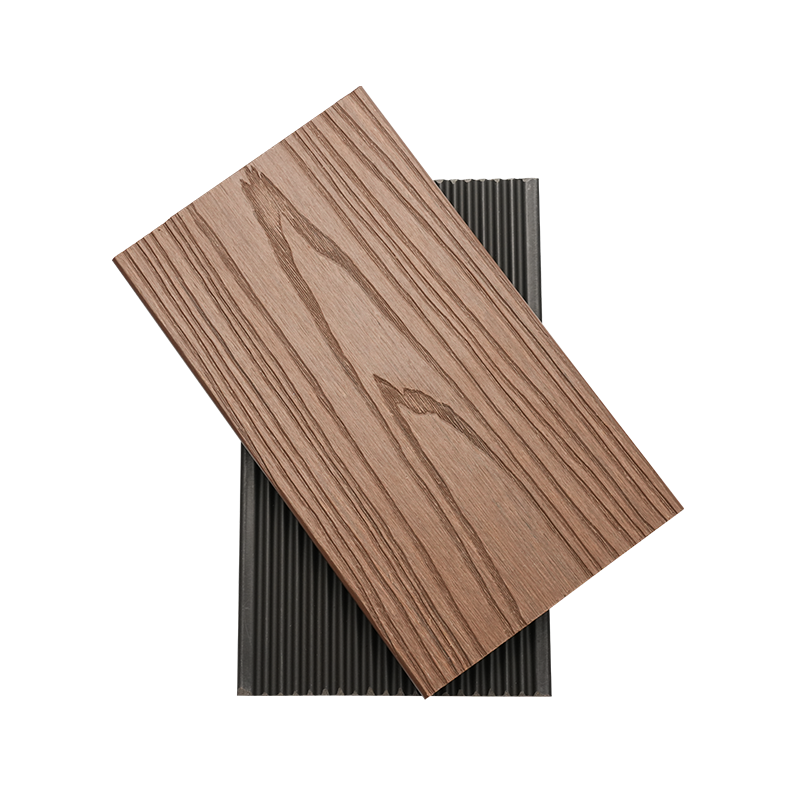

The straight-grained surface pattern complements this structure. Rather than random wood-like swirls, the boards feature consistent parallel grooves that enhance traction and visual uniformity.

Functional Benefits for Homeowners and Builders

Real-world applications highlight why this design is practical as well as scientific:

- Easier Handling: Boards weigh less, allowing faster installation and reducing labor costs.

- Slip Resistance: The grain grooves improve grip, a vital feature for families, poolsides, or public decks exposed to rain.

- Aesthetic Longevity: The parallel grain helps conceal scratches and wear, keeping the deck visually consistent for years.

- Low Maintenance: Unlike timber, there is no annual sanding, sealing, or staining—only basic washing.

Comparing to Alternatives

When compared to pressure-treated wood, tropical hardwood, or older composites, this decking shows measurable advantages:

- Time Savings: Owners avoid 10–15 hours of yearly maintenance, freeing time for actual enjoyment of outdoor spaces.

- Cost Efficiency: Though initial investment is higher than timber, lifecycle costs are lower over a 20–25 year span.

- Eco-Friendliness: Boards are made with recycled wood fibers and plastics, reducing reliance on virgin materials and deforestation.

For commercial projects—like waterfront promenades or hotel terraces—the balance of durability and light weight makes this product particularly attractive.

Best Practices for Installation

To unlock full performance, installation must follow precise guidelines:

- Joist Spacing: Maintain 16-inch spacing to support the hollow structure.

- Fastening Systems: Use hidden clips that allow natural expansion and contraction.

- Proper Slope: Build a slight incline to aid water flow through the channels.

Following these standards prevents flexing, ensures longevity, and maximizes safety.

Industry Contribution and Market Trends

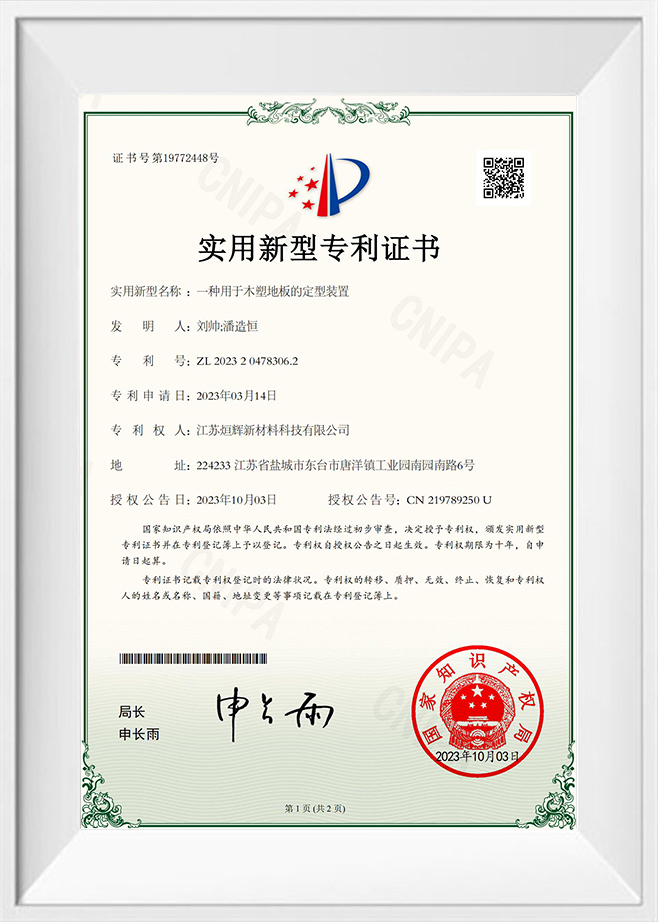

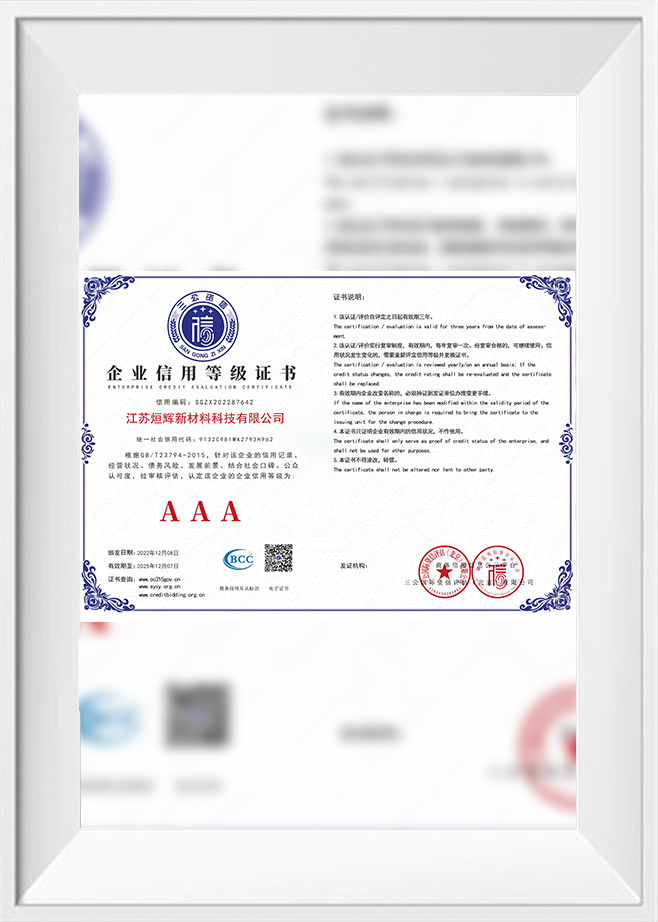

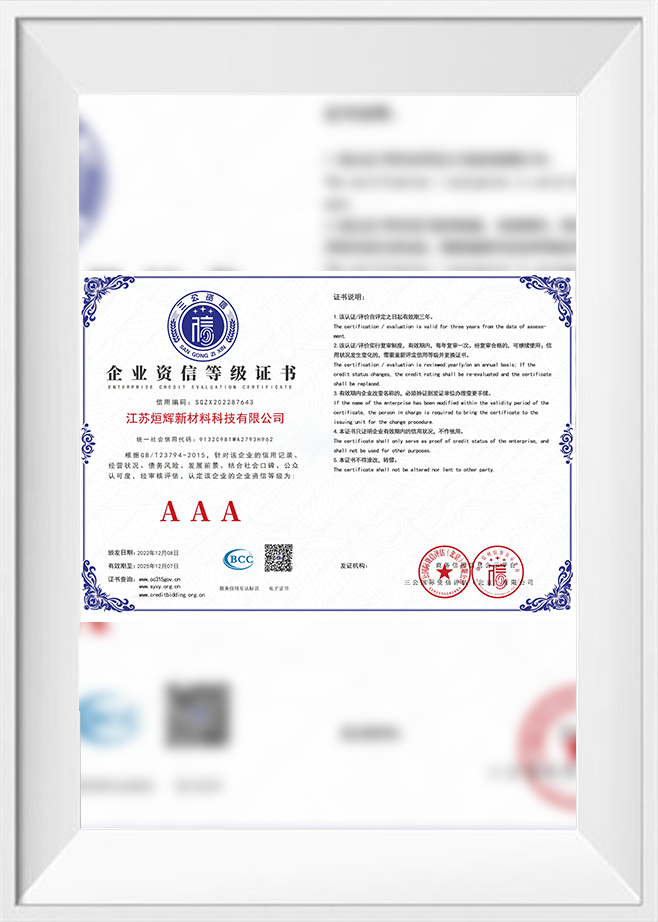

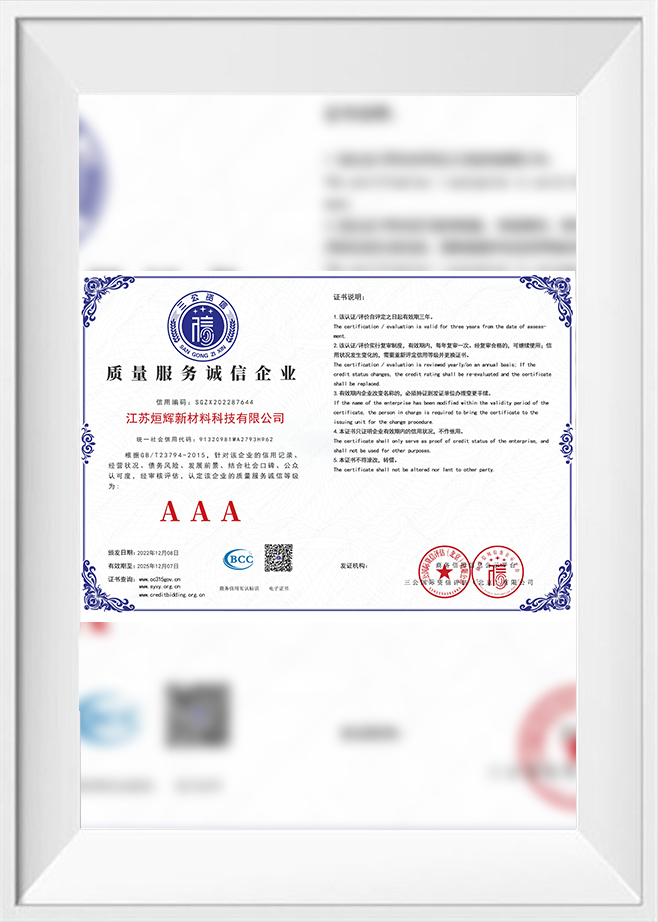

The rise of such advanced profiles reflects broader global trends: construction sectors now prioritize sustainability, performance, and safety. In regions like Jiangsu, China, manufacturers such as Jiangsu Xuanhui New Material Technology Co., Ltd. have invested in precision extrusion and material research. Their innovations have helped establish global benchmarks for composite decking quality—aligning with green-building certifications and international durability standards.

Market demand is also accelerating. Homeowners want eco-conscious yet stylish outdoor solutions, while developers seek materials that reduce maintenance costs in high-traffic areas. Six-hole straight-grained composites are positioned to meet both demands.

Looking Ahead: The Future of Composite Decking

The evolution of decking is far from complete. Ongoing research is exploring:

- Smart Decking: Boards embedded with sensors to track load, temperature, and moisture.

- Enhanced Recyclability: Next-generation composites designed for easier end-of-life reuse.

- Advanced Surfaces: Nanotechnology coatings that self-clean or resist stains more effectively.

In this trajectory, six-hole designs serve as a strong foundation—proving how structural engineering and aesthetic considerations can work together.

Conclusion: A Balanced, Future-Ready Choice

Six Hole Straight-Grained Wood Plastic Decking is more than a stylish alternative to wood; it is a scientifically engineered solution that balances strength, thermal performance, moisture resistance, and visual appeal. For homeowners, it provides safety, durability, and reduced maintenance. For builders and developers, it offers efficiency, long-term value, and sustainability.

In a world where outdoor living is increasingly central to both lifestyle and architecture, this decking configuration stands out as a smarter, future-ready choice that reflects the best of modern material science.

English

English Español

Español عربى

عربى