Is Seven Hole Embossed Wood Plastic Decking the Ultimate Upgrade for Outdoor Living?

Rethinking Outdoor Decking Choices

When planning an outdoor space, the decking surface is more than a background element—it is the foundation of how the space looks, feels, and performs over decades. The right material must balance durability, safety, aesthetics, and environmental responsibility. Traditional wood has long been favored for its natural charm, while first-generation composites offered an early alternative. But as user demands and climate challenges evolve, a more advanced option is stepping into the spotlight: Seven Hole Embossed Wood Plastic Decking.

This innovative product is not a simple variation of existing boards; it is a carefully engineered solution that addresses weaknesses in both timber and early composites, reshaping the standards for modern outdoor living.

What Exactly Is It?

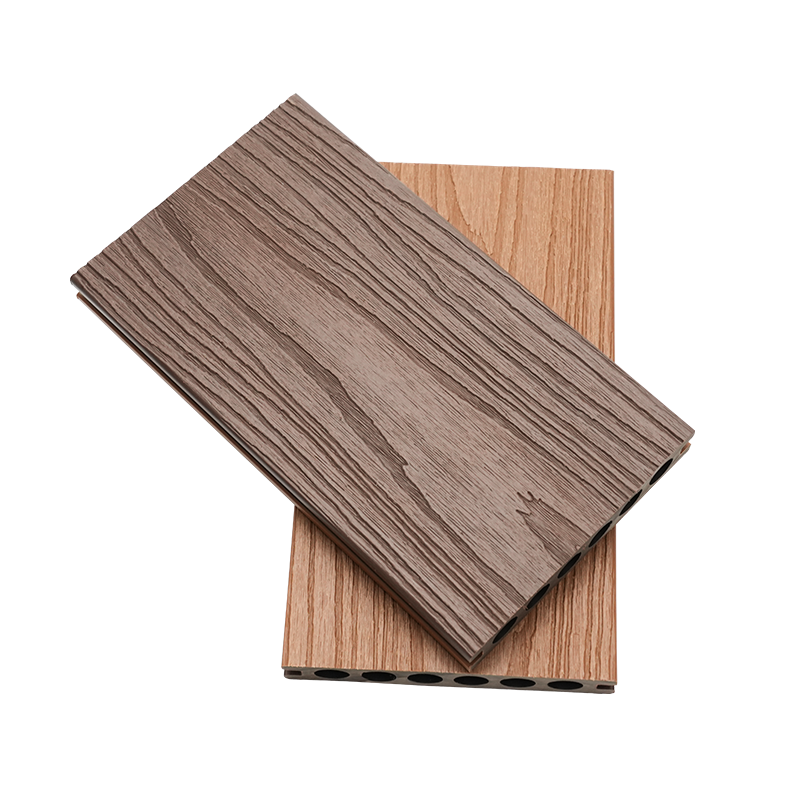

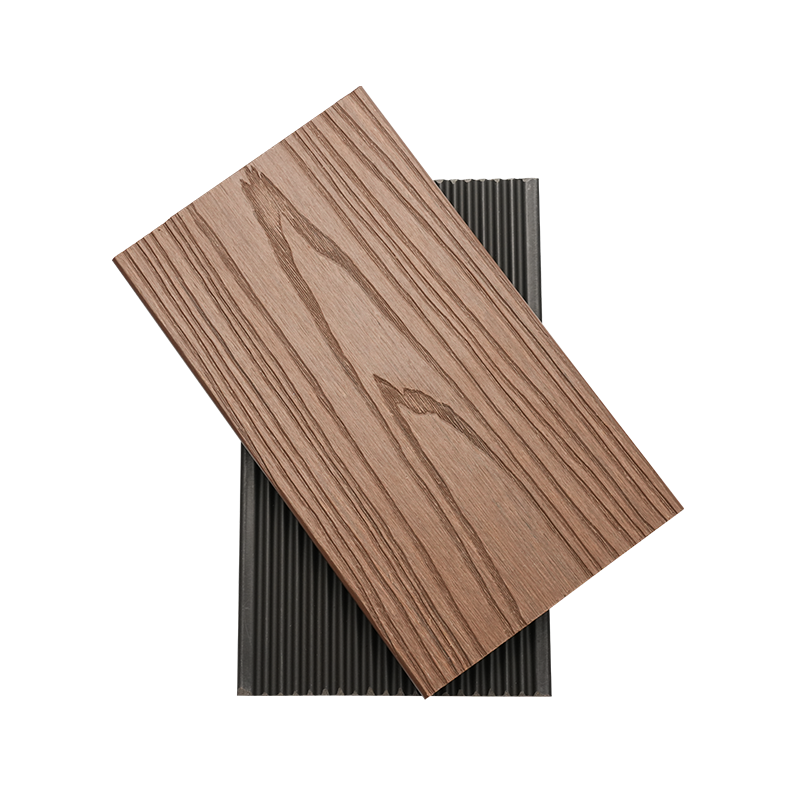

At its core, this type of decking is a composite blend of recycled wood fibers and thermoplastic polymers. What distinguishes it are two defining features:

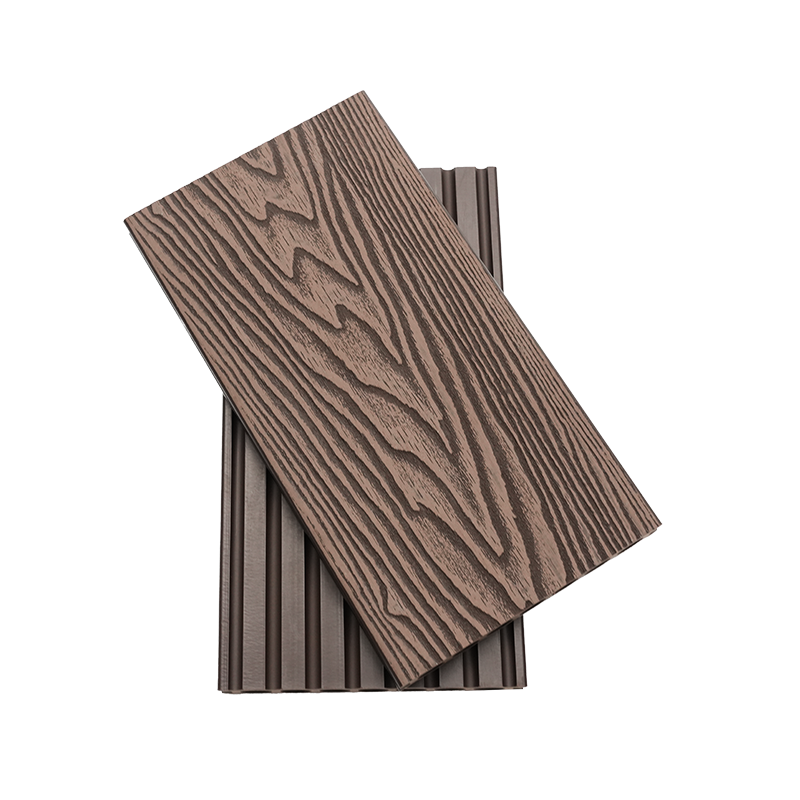

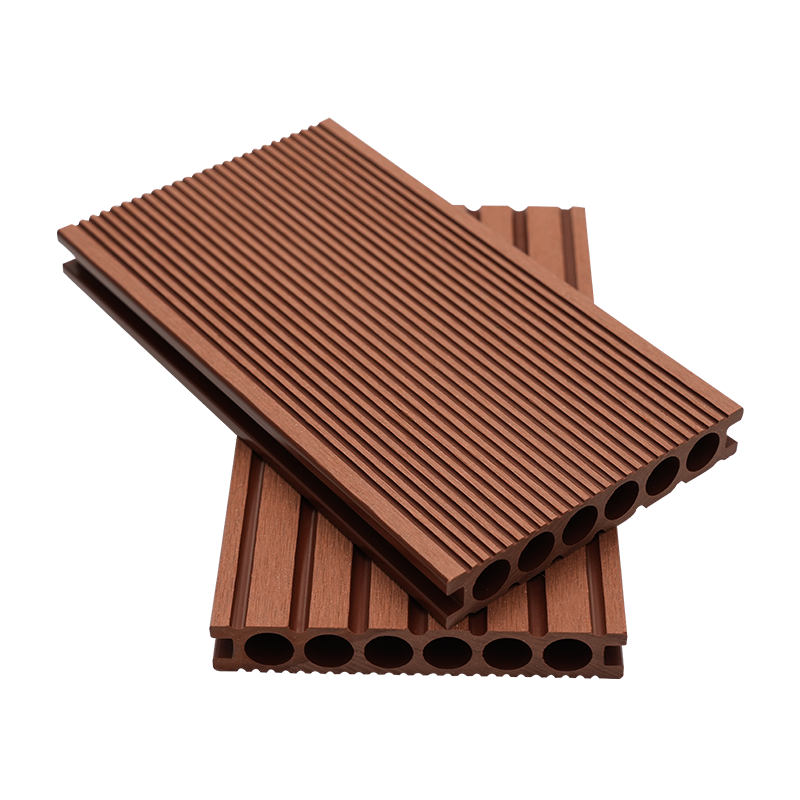

- Seven-Hole Hollow Core: Seven equally spaced channels run lengthwise through the board. This structural choice is rooted in engineering science, offering a lightweight yet remarkably strong profile.

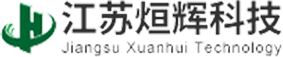

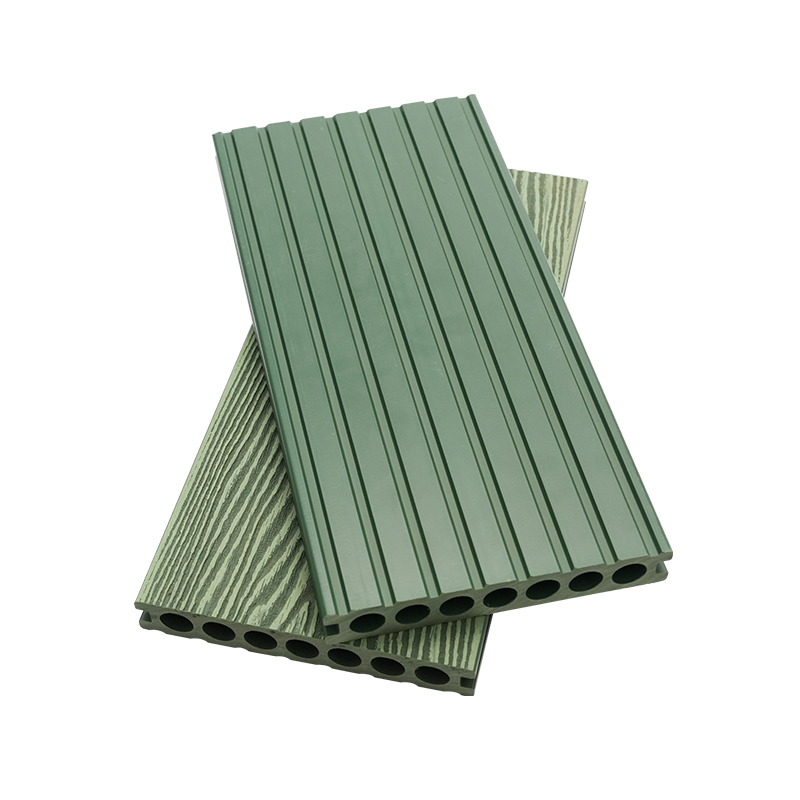

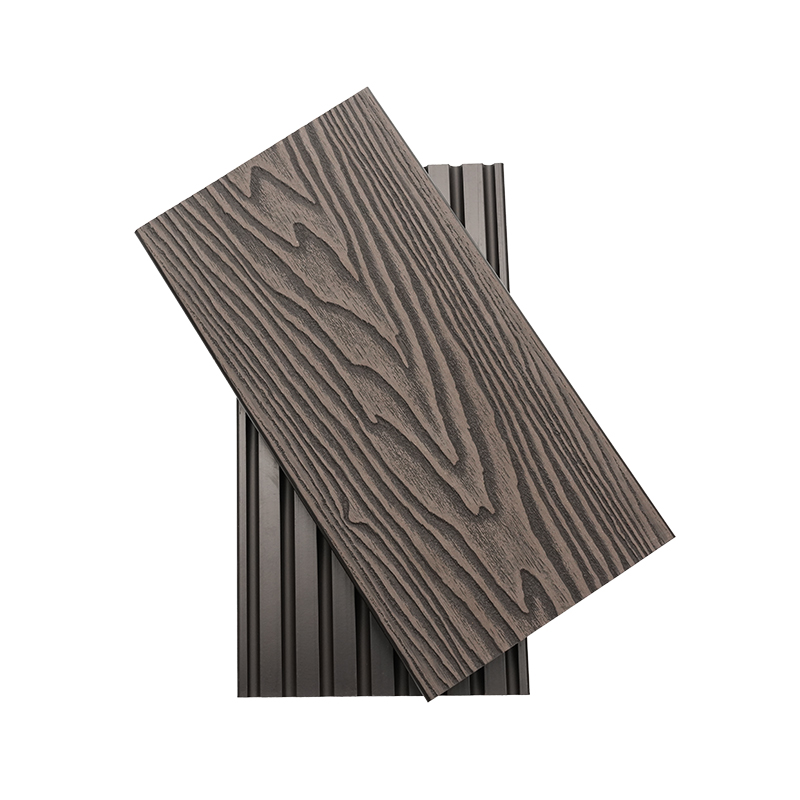

- Embossed Surface Texture: A deep, wood-like grain is pressed into the surface during manufacturing. Unlike shallow patterns that fade quickly, this embossing creates a lasting tactile and visual resemblance to real timber.

The result is a board that combines the stability of composite technology with thoughtful design enhancements aimed at real-world performance.

Engineering Advantages of the Seven-Hole Design

The seven-hole layout is not just aesthetic—it directly impacts function and durability.

- Strength-to-Weight Efficiency: Similar to the principle of I-beams in construction, the hollow channels ensure that material is concentrated where it provides maximum resistance against bending and sagging. This allows the boards to handle heavy foot traffic and furniture without excessive weight.

- Thermal Stability: Outdoor materials expand and contract with heat and cold. The hollow chambers provide “buffer zones” for this natural movement, reducing surface stress and minimizing warping or buckling.

- Drainage and Airflow: Water passes through more easily, reducing the risk of pooling, mold, or mildew. Improved ventilation beneath the deck accelerates drying, protecting both the boards and the supporting frame.

Why the Embossed Surface Matters

Surface technology directly affects safety and appearance.

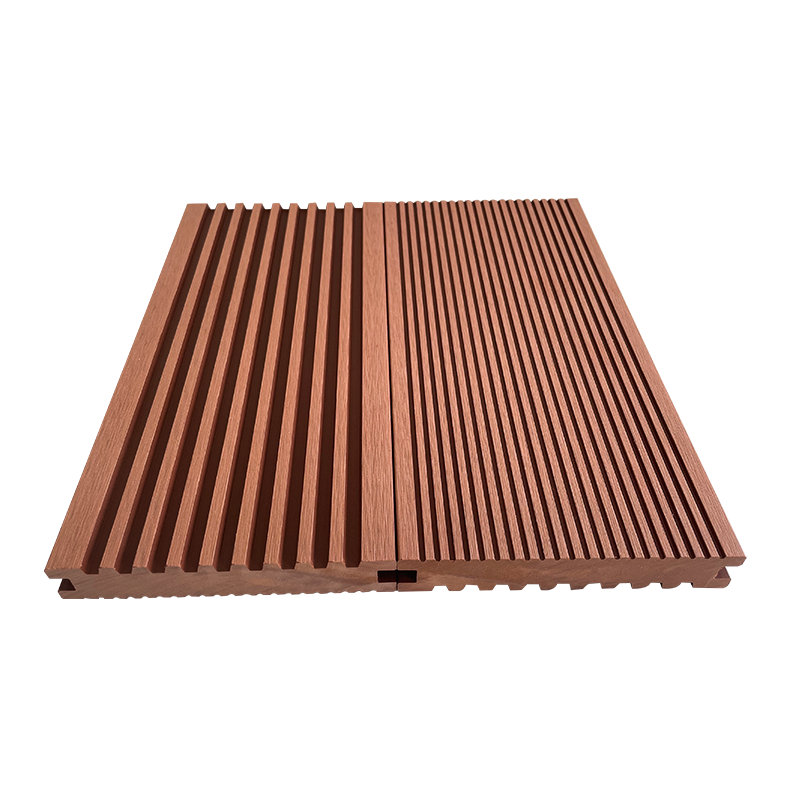

- Slip Resistance: Deep embossing creates micro-grooves that provide superior traction, even when wet. This is a critical safety feature around pools, in rainy regions, and in family-friendly environments.

- Authentic Look: High-definition embossing replicates exotic hardwoods without the ecological cost of logging rare species. Unlike painted or film-coated boards, the texture feels natural and helps disguise everyday scuffs.

- UV Performance: The uneven surface helps diffuse sunlight, slowing visible fading and maintaining color richness over years of exposure.

Performance Benefits Over Traditional Options

Compared to solid timber or early composites, this new generation offers:

- Durability: Immune to termites, rot, and splintering.

- Low Maintenance: No need for painting, sealing, or staining—just periodic washing.

- Safety: Enhanced grip underfoot, with reduced risk of slipping accidents.

- Sustainability: High recycled content, longer lifespan, and reduced need for chemical treatments.

These attributes make it ideal not only for residential decks but also for hotels, resorts, waterfront boardwalks, and public recreation areas.

Practical Considerations for Use

To maximize performance, proper installation and product selection are essential.

- Substructure: A stable, well-leveled joist system is necessary to support hollow-core decking.

- Fastening Systems: Hidden clips are often recommended, creating a clean finish and allowing for controlled expansion.

- Quality Markers: Look for high wood-fiber ratios for rigidity and dense profiles that resist deformation. Products with protective polymer caps provide extra resistance against UV rays and surface wear.

Broader Market and Industry Innovation

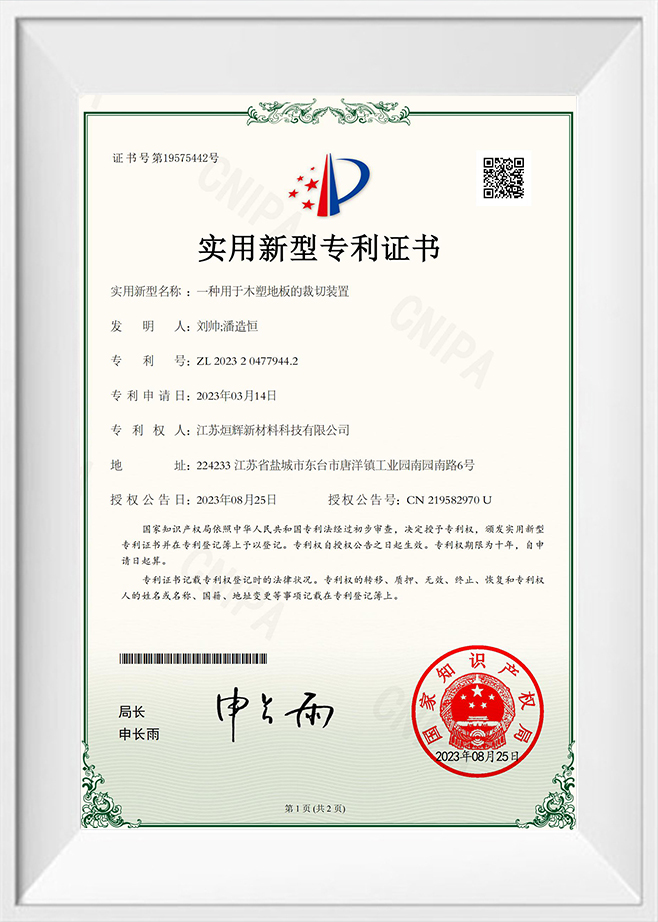

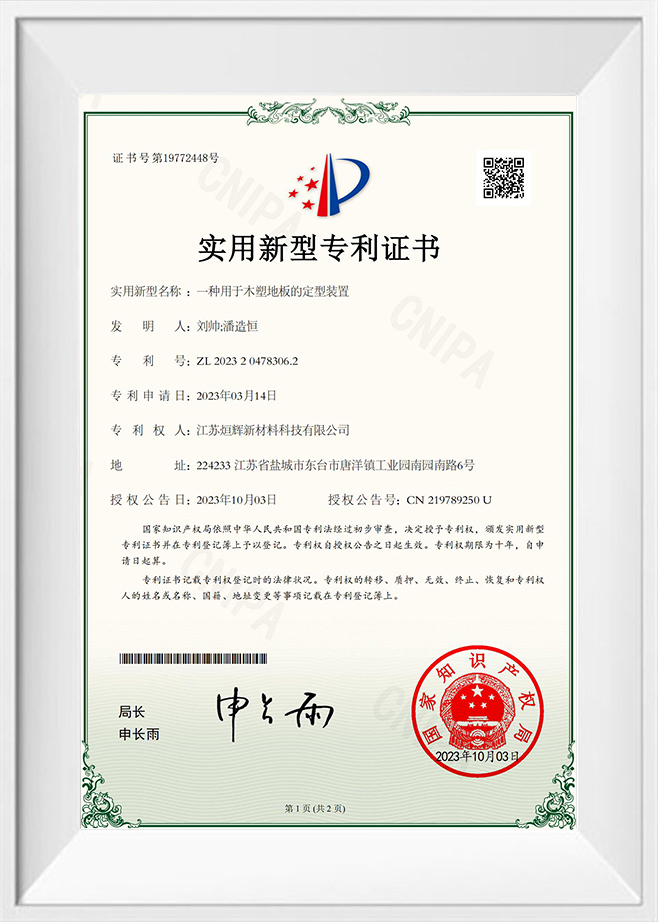

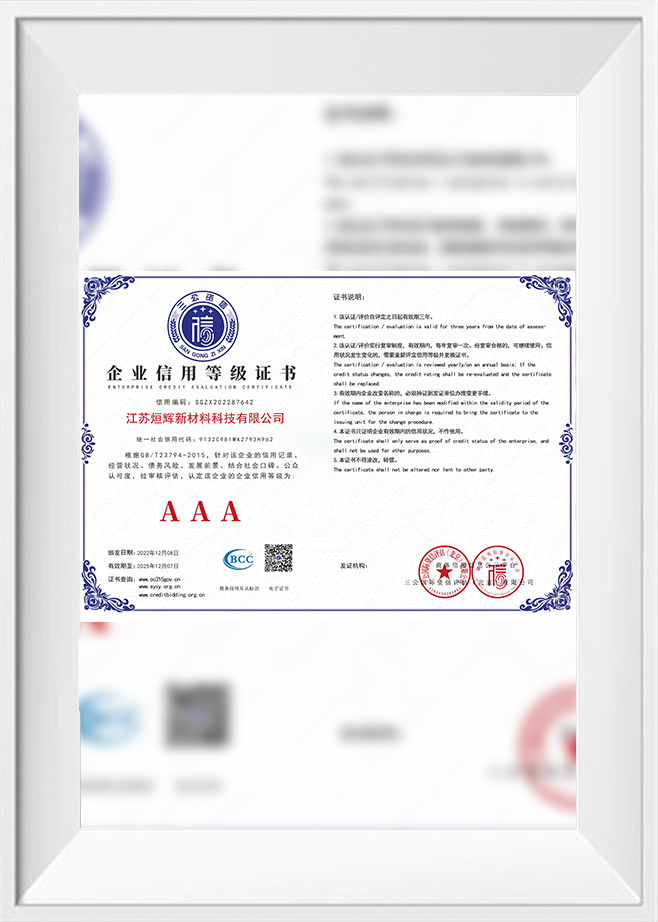

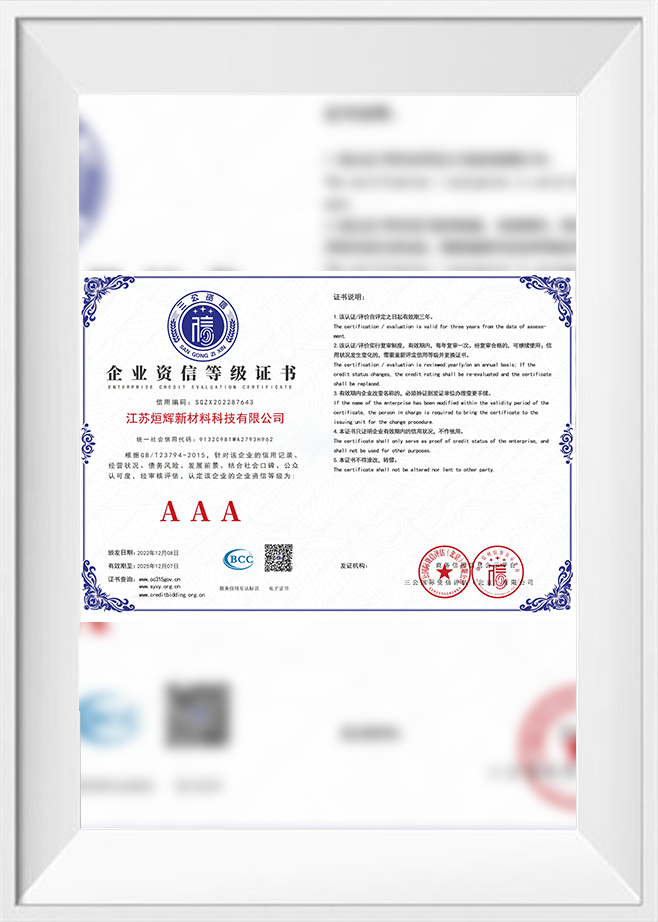

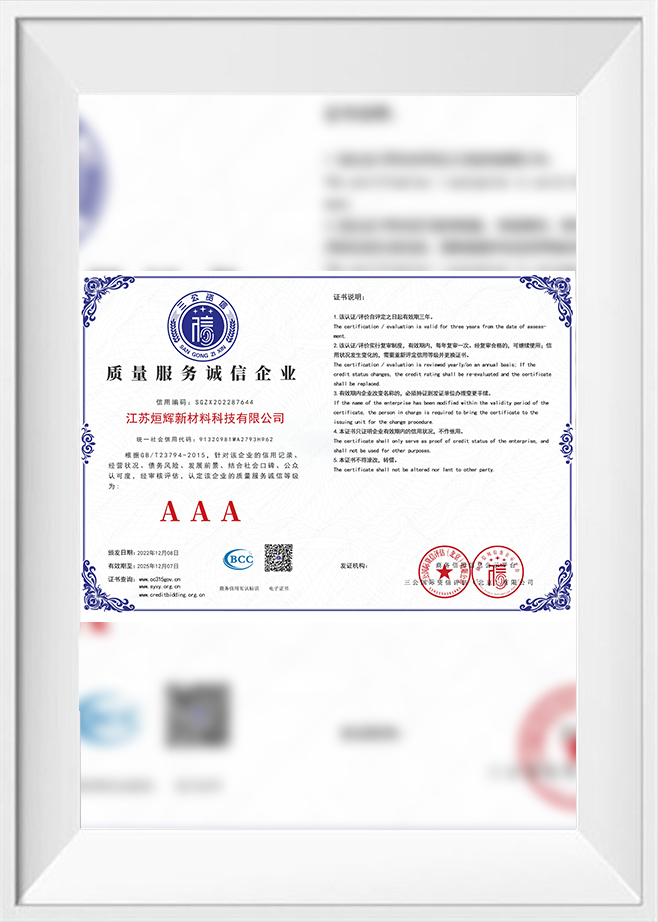

The development of specialized products like this is part of a wider trend in construction: combining material science with sustainable design. Manufacturers, such as Jiangsu Xuanhui New Material Technology Co., Ltd., are investing heavily in advanced extrusion processes, co-extrusion caps, and surface technologies. Their efforts ensure products meet global expectations for safety, beauty, and longevity.

This aligns with international building trends, where cities and communities are demanding materials that require less maintenance, last longer, and contribute to green-building certifications.

Conclusion: Engineering Meets Lifestyle

Seven Hole Embossed Wood Plastic Decking is not just another option in the marketplace—it represents a carefully engineered upgrade that resolves long-standing issues with both wood and early composites. Its hollow structure provides strength, stability, and drainage benefits, while the embossed surface delivers both safety and natural aesthetics.

For homeowners seeking peace of mind, architects focused on sustainable design, and developers aiming for long-term value, it is a clear investment in the future of outdoor living. By merging structural science with design innovation, this decking shows how far materials technology has come—and where the future of outdoor architecture is heading.

English

English Español

Español عربى

عربى